3. Product Preparation

Immediate trim and selection of hides ensures prompt feedback, allowing for instant action in controlling possible flays or quality problems caused by an abattoir. Any excess material which is not needed for leather production, following the approved German trimming standards, is removed by our skilled staff to maximize the area of available hide and minimizing any waste to the tanner.

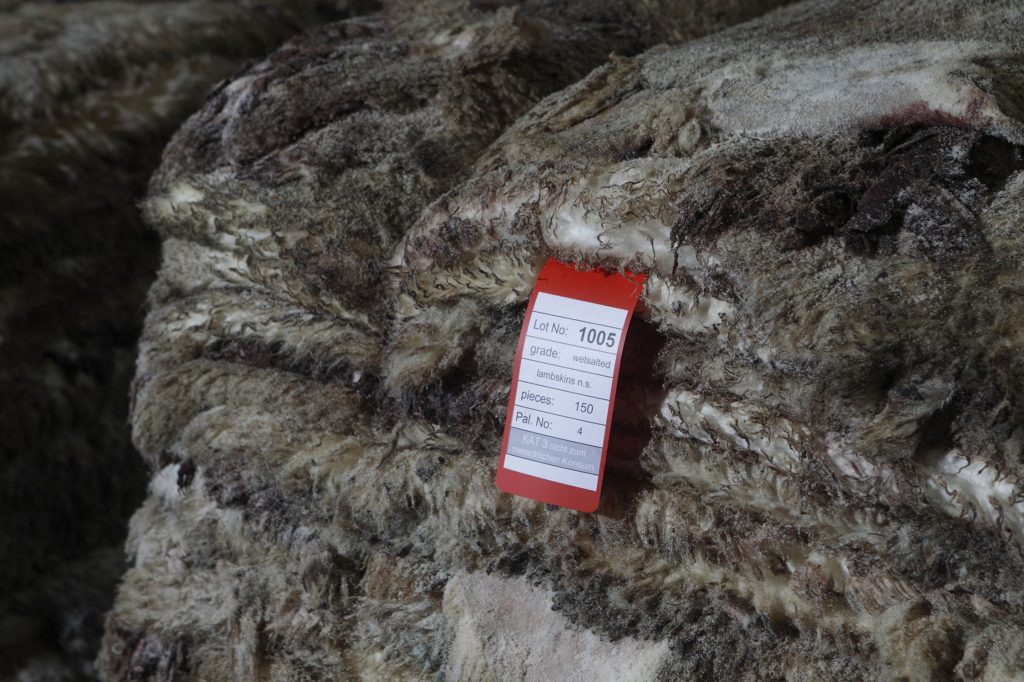

Hides are sorted after being weighed on the computer scale and then travel up the conveyor, which sorts them according to weight and grade. Wet salted conventional hides for sale to customers world wide receive a treatment period including salt and pressure required for moisture removal and preservation. Each hide is individually salted on all corners by hand guaranteeing optimal quality and the entire usage of each and every hide.

Hides then travel to the computer scale where they are weighed, taking the moisture, manure, fat and the general condition of the hide into account for the preparation of consistent yield figures and exact delivery details for tanners. In addition, each hide is individually controlled and selected by our skilled hide specialist. Further, our real time computer stock controlling system allows for constant monitoring of hide weights and quality needed for our reliable and on time production schedule. Our computer supported recording and sorting process has set the standard of quality for years and remains the requirement for a complete and long term quality control program.